Hermetic feedthroughs are critical components in industries requiring airtight or vacuum-sealed environments, including aerospace, medical devices, semiconductor manufacturing, and industrial systems. As technology advances, hermetic feedthroughs are evolving to meet higher demands for performance, reliability, and miniaturization. Innovations in materials, design, and manufacturing processes are transforming how engineers approach electrical, optical, and fluid connections in high-tech applications.

The Need for Innovation

Traditional hermetic feedthroughs, such as glass-to-metal and ceramic-to-metal designs, have provided reliable performance for decades. However, modern high-tech devices require smaller form factors, higher signal densities, greater thermal and mechanical tolerance, and improved electrical performance. As industries demand miniaturization, high-speed data transmission, and enhanced durability, feedthrough technology is being reimagined to meet these challenges.

Advanced Materials

One major innovation in hermetic feedthrough is the development of advanced materials:

- High-performance ceramics: Alumina and other engineered ceramics now offer better thermal stability, higher dielectric strength, and improved mechanical resilience.

- Specialty glasses: New glass compositions reduce thermal mismatch with metals, preventing cracks and improving vacuum sealing.

- Metal alloys: Custom metal alloys, such as Kovar or titanium, provide enhanced corrosion resistance, thermal expansion compatibility, and mechanical durability.

These materials allow feedthroughs to perform reliably in extreme environments, including cryogenic systems, high-voltage equipment, and corrosive industrial settings.

Miniaturization and High-Density Feedthroughs

Modern electronics require smaller devices with higher signal density. Innovations in miniaturization have enabled:

- Micro hermetic feedthroughs: Extremely small form factors for implantable medical devices and microelectronics

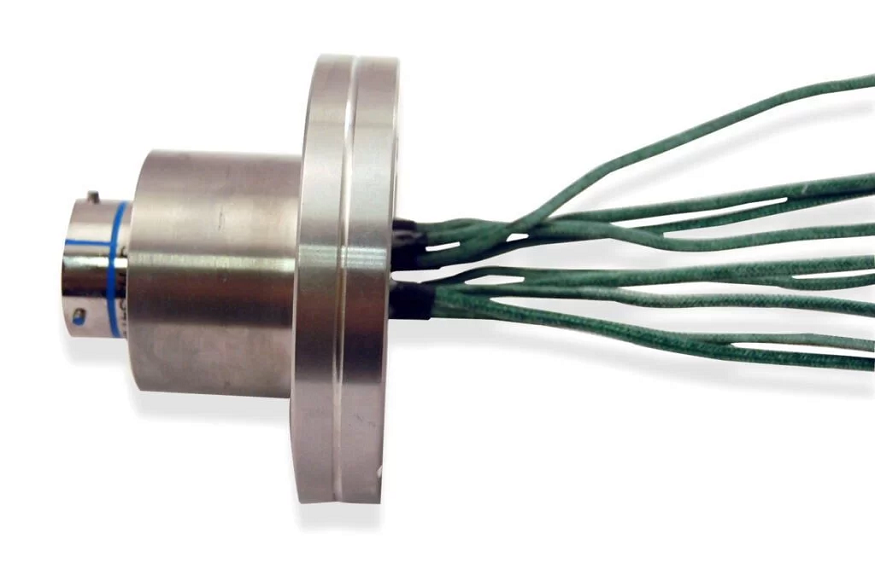

- High-density multi-pin designs: Allow dozens or even hundreds of connections through a single sealed barrier, reducing space requirements while maintaining reliability.

- Fine-pitch feedthroughs: Improved pin spacing supports high-speed data transmission without signal interference.

These advances make hermetic feedthroughs suitable for compact, high-performance systems, including satellites, implantable medical devices, and advanced industrial sensors.

Enhanced Electrical and Optical Performance

Hermetic feedthroughs are increasingly designed to handle high-frequency signals, high-voltage applications, and optical data transmission. Innovations include:

- Coaxial hermetic feedthroughs: Provide consistent impedance for RF and microwave signals while maintaining vacuum integrity.

- Optical fiber feedthroughs: Allow secure transmission of optical data through sealed barriers with minimal signal loss.

- High-voltage feedthroughs: Advanced insulation and spacing techniques prevent arcing and improve safety in power systems.

These innovations expand the applications of hermetic feedthroughs into telecommunications, satellite communications, and high-speed industrial automation.

Improved Sealing and Reliability

Innovations in sealing techniques have enhanced the long-term reliability of hermetic feedthroughs:

- Brazing and laser welding: Provide stronger, more precise seals than traditional soldering methods.

- Advanced glass and ceramic bonding: Reduces the risk of micro-cracks and ensures consistent vacuum or pressure sealing.

- Enhanced environmental resistance: New designs withstand vibration, thermal cycling, and corrosive environments better than ever.

These improvements reduce maintenance requirements and increase the lifespan of critical systems.

Customization and Modular Designs

Modern hermetic feedthroughs are increasingly customizable to meet unique industry requirements:

- Modular assemblies: Allow engineers to combine multiple feedthrough types in a single unit for complex systems.

- Tailored materials and coatings: Ensure compatibility with specific environmental or operational conditions.

- Rapid prototyping and 3D manufacturing: Enable faster development cycles and adaptation for cutting-edge technologies.

Customization ensures that hermetic feedthroughs can meet the demanding specifications of aerospace, medical, industrial, and scientific applications.

Future Trends in Hermetic Feedthrough Technology

The future of hermetic feedthroughs is focused on:

- Integration with smart sensors: Embedding sensors within feedthroughs for real-time monitoring of temperature, pressure, and humidity.

- Ultra-miniaturization for IoT and wearable devices: Smaller, lighter feedthroughs for consumer and medical applications.

- Advanced coatings and surface treatments: Enhancing corrosion resistance, conductivity, and sealing properties.

- High-speed optical and RF feedthroughs: Supporting next-generation communications and industrial automation systems.

These trends will continue to expand the capabilities of hermetic feedthroughs across multiple high-tech industries.

Conclusion

Hermetic feedthrough technology is evolving rapidly to meet the demands of modern high-tech applications. Innovations in materials, miniaturization, electrical and optical performance, sealing techniques, and customization have expanded the applications of these components across aerospace, medical, industrial, and scientific fields. By embracing these technological advancements, engineers and manufacturers can ensure their systems maintain environmental integrity, reliability, and performance in increasingly complex and demanding environments.