Nothing lasts forever. However, some things last a lot longer than others. Modern industries face enormous pressure to build products that can handle years of abuse while keeping customers happy. The secret lies in smart design choices that put durability first. Even when it costs more upfront.

Why Durability Matters More Than Ever

Today, people expect the stuff they buy to keep working right for a long, long time. They don’t want fridges to quit after a couple years or tablets needing repairs every other month. A single bad tweet or video can bring a brand to its knees, and fixing the damage isn’t cheap.

On top of that, governments are passing tougher rules to protect the planet. They want products that stick around longer so we throw away less. Building something once that works for decades makes more sense than building ten cheap versions that break constantly. This shift changes how engineers think about every design decision.

Materials That Stand the Test of Time

Picking the right stuff for a project can make or break the whole thing. Steel is solid for a lot of jobs, but in a salty environment, it’ll rust. Plastic is light and cheap, but can break into pieces if it gets too hot or too cold. Smart engineers tailor materials to product needs.

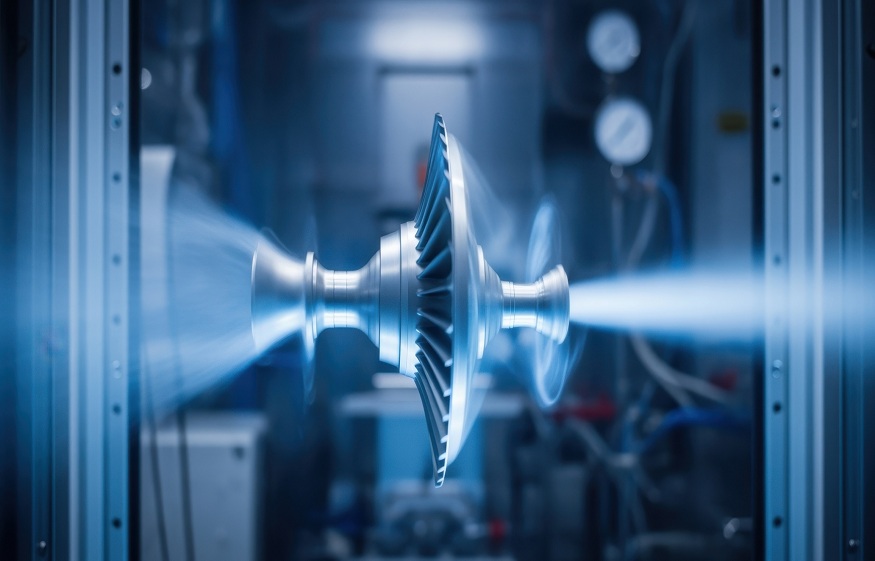

Industrial composites combine different materials to get the best of both worlds. The experts at Aerodine Composites explain that these advanced materials not only resist corrosion. They also handle extreme temperatures and maintain their strength for decades. They cost more initially but save money over time by lasting longer and requiring less maintenance.

Learning From Failure

Every time something breaks, it hands out a lesson. Engineers pull apart failures to find out what happened. Was the part built wrong, made with the wrong material, or did it get hit with stress nobody saw coming? Each mistake is a way to get smarter and build something stronger.

Some industries have lived through the lesson. Old wind turbines kept crashing because the first teams didn’t believe the wind could be that strong. Today’s turbines are built with decades of crash history, and they can spin for twenty years or more without drama.

Testing Beyond Normal Limits

Durability testing is all about pushing stuff way past what people will actually put it through. Engineers blast parts with super-hot and super-cold air, shake them until they rattle apart, and crush them with way more force than they’d ever feel in the field. Machines might run non-stop for months, pretending they’ve lived for years.

Big climate rooms freeze a product until it’s colder than any artic trip and then bake it hotter than a desert truck stop. Vibration beds rattle them until they crack. Saltwater sprays blast everything for days, simulating years of ocean air. All these beatings show where stuff will fail long before customers ever get their hands on it.

Industry-Specific Demands

Every industry has its own tests for keeping things working tough. Aerospace needs to get it right because human lives are literally on the line. Construction machinery runs through mud, rain, and hard hits every day and comes back for more. Medical gear needs to deliver the same lifelike readings or perfect doses day after day, for years straight, without a hiccup.

Conclusion

Making gear that lasts is more than just slapping on extra metal. It’s about building stuff that customers count on, that leaves a smaller footprint on the planet, and that saves cash in the long run. The companies that nail this will grab the market while the ones stuck in the repair shop lose customers and cash.